| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Brand Name | Nagpal Natraja |

| Voltage | 380V |

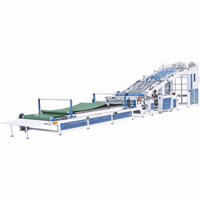

| Gluing Machine | board gluing machine |

| Click to view more | |

Product Details

-

High-Precision Engraved Applicator Roll

-

Ensures even adhesive application

-

Reduces adhesive consumption

-

-

Auto-Circulating Glue Feeding

-

Prevents glue depositing

-

Ensures continuous and efficient glue supply

-

-

Self-Preheating Device

-

Accelerates glue gelling

-

Enhances bonding strength

-

-

Roller Surface Treatments

-

Glue Roller: Embossed netting design, chrome plated

-

Doctor Roller: Ground and chrome plated

-

Pressure Roller: Chrome plated

-

-

Roller Heating & Control Systems

-

Equipped with preheating rollers

-

Pressure Roller: Pneumatically controlled up-down adjustment

-

Gap Adjustments:

-

Between glue roller & doctor roller

-

Between glue roller & pressure roller

-

Controlled by electric micro-adjustment with digital readouts

-

-

-

Maximum Working Speed: 150 m/min

-

Working Temperature Range: 160–200°C

-

Steam Pressure: 1.0 – 1.4 MPa

-

Steam Consumption: 0.4 – 0.6 T/h

-

Compressed Air Pressure: 0.4 – 0.9 MPa

| Main Motor | 380V AC | 3 KW | Continuous Work |

| Glue Adjustment Motor | 380V AC | 100 W | Short Time Work |

| Pump Motor | 380V AC | 2.2 KW | Continuous Work |

| Preheating Roller | 416 mm | Chrome plated after grinding |

| Paper Leading Roller | 108 mm | Chrome plated after grinding |

| Pressure Roller | 171 mm | Chrome plated after grinding |

| Glue Roller | 290 mm | Chrome plated after grinding |

| Doctor Roller | 168 mm | Chrome plated after grinding |

General Specifications

| Working width mm | 1600 |

| Direction | Left or right, according to customer |

| Mechanical speed | 150mm/min |

| Temperature | 130~200oC |

| Steam pressure Consumption |

1.0~1.6MPa 0.45 t/h |

| Compressed Air | 0.4~0.9MPa |

The performance index may be variant according to the below situation:

- Quality of paper mill

- Steam saturation level

- Condensed water drain flow

- Glue quality

Roller Diameter

| Name of Roller | Diameter | Treatment |

| Pre-heater roller | 400mm | Hard Chrome and grinding |

| Paper guiding roller | 120mm | Hard Chrome and grinding |

| Contact roller | 120mm | Hard Chrome and grinding |

| Engraving roller | 254mm | Hard Chrome and grinding |

| Gluing roller | 150mm | Hard Chrome and grinding |

Specifications

| Motor | Voltage | Property | Power | Working mode | ||

| Main drive motor | 380V | AC | 1600mm | -- | ||

| 2.2Kw*2 pics | S1 | |||||

| Motor for glue quantity adjustment | 380V | DC | 100w | S2 | ||

| Glue pump motor | 380V | AC | 1.5Kw | S3 | ||

Note : S1 is of constant working mode; S2 is of non constant working mode.

| Total Capacity | ||||||

| Width | 1600mm self-drive | |||||

| Capacity | Double side | 6.1Kw | ||||

Power : 5~15Kw 380VAC 50Hz 3×15~3×40A

Looking for "Nagpal Duplex Gluing Machinery" ?

Explore More Products